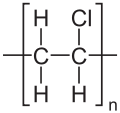

Vinyl plastic is a rigid thermoplastic opaque plasticizer- free plastic material based on polyvinyl chloride and perchlorovinyl resin , which also contains thermal and light stabilizers , antioxidants that prevent the destruction of material during processing and operation, lubricants (facilitating its processing and processing), pigments or dyes , for color products. It is a polymer product.

Another name is unplasticized polyvinyl chloride (NPVC).

To improve operational properties and reduce cost, up to 35% (by weight of polymer ) modifiers ( chlorinated polyethylene , rubbers ), up to 20% of fillers ( chalk , soot , aerosil ) and up to 10% of plasticizers are introduced into the composition of vinyl plastic.

Viniplast can be glued to concrete, wood and metal surfaces.

Content

Properties

Viniplast is non-flammable and odorless . In addition, vinyl plastic lends itself well to various types of machining . Viniplast is easily welded at a temperature of 230-250 degrees Celsius using a welding rod and glues well with various types of glue, prepared on the basis of polyvinyl chloride and perchlorovinyl resin. It should be noted that welded and adhesive joints, whose strength is 80-90% of the strength of the material, lend themselves well to machining.

Viniplast is a good dielectric when operating products within + 20-80 degrees Celsius, but it should be borne in mind that when a vinyl plastic product is heated above +80 degrees Celsius, a sharp drop in dielectric properties occurs. Viniplast is resistant to acids , alkalis and aliphatic hydrocarbons , but unstable to aromatic and chlorinated hydrocarbons.

Manufacturing

Viniplast is obtained by mixing the components in high-speed mixers, followed by processing the dry mixture on rollers or in extruders , sometimes with its preliminary granulation.

It is processed into products by extrusion , pressing and injection molding .

The processing methods of vinyl plastic depend on the type of product being produced:

- Film-based vinyl plastic is obtained by rolling ( calendering ) a vinyl-plastic mass;

- Smooth vinyl-plastic sheets - by pressing bags assembled from a vinyl-plastic film and extrusion ;

- Small vinyl-plastic products of various profiles - injection molding from granules on injection machines, as well as by pressing tablets or a powder mixture;

- Vinyl- plastic pipes , profiled products and corrugated vinyl-plastic sheets - by extrusion from granules;

- Large vinyl-plastic products of complex configuration - vacuum molding from sheets on molding machines.

Application

It is used for the manufacture of pipelines , containers, sheets, profiles in construction, chemical engineering, etc.

Since it has good bending strength and elasticity , fishermen sometimes make upper parts of spinning rods (whips) and winter fishing rods made of vinyl plastic using the artisanal method. With appropriate processing, such parts allow bending of more than 45 degrees.

See also

- Viniplast sheet industrial

- Vinyl-plastic pipe

- Vinyl-plastic bar

Literature

- Chemical Encyclopedic Dictionary. Ch. ed. I.L. Knunyants. - M.: Soviet Encyclopedia, 1983-792 p.