Scales - a device or device for determining the mass of bodies ( weighing ) according to the weight acting on them, approximately considering it equal to the force of gravity [1] . Body weight can be determined both by comparison with the weight of the reference mass (as in the scale of the balance), and by measuring this force through other physical quantities.

In addition to the independent use of the scales can be the main element of the automated system of accounting and control of material flows. This ensures the operational management of production and allows you to increase production volumes, improve the quality and profitability of products, while reducing costs and costs.

History

The first samples of scales found by archeologists belong to the V millennium BC. e., they were used in Mesopotamia [2] [3] .

Scales are clearly visible on the papyrus of the XIX dynasty (about 1250 BC). According to the ancient Egyptian "Book of the Dead", Anubis , at the entrance to the underground kingdom weighs the heart of everyone who dies on special scales, where the feather of justice is the goddess Maat .

Stone stele I millennium BC. e. (Turkey) depicts a Hett that uses its own finger instead of a transverse bar of balance weights [3] .

Historians attribute to the Romans the invention of a fundamentally new system for measuring weight - at which the weight moves, while the fulcrum and the position of weight gain remain unchanged [3] . In Pompeii, one of the earliest humenys was found [2] [3] . The Roman device, in contrast to the modern, had two scales and two handles in the form of hooks.

In ancient Russia, goods were weighed on equal-shoulder scales - bow. From the XIV century , the word " bezmen " appears in Russia (a measure of weight equal to 1.022) [4] .

Principle of action

Lever Scales

Lever scales are scales in which the transfer device is a lever or a system of levers.

Equal Shoulder Scales

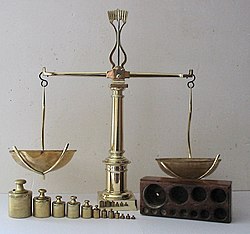

Scales

In equal shoulder arm weights, the point of load suspension (m1 and m2) and the fulcrum point form an isosceles triangle ( yoke ) with height h and apex at the fulcrum point. With the rotation of an isosceles triangle (rocker) through the angle α, one arm increases and the other decreases. The rotation of the rocker arm stops when the torques are equal: m1 * l1 = m2 * l2, m1 / m2 = l2 / l1, where l 1 and l 2 are the shoulders of the torques. The angle of rotation of the rocker arm can be calibrated in units of mass ( quantity ). The smaller the height of the triangle is h, the smaller the change in shoulders when turning and the greater the sensitivity of the scales. Such a device corresponds to a state of stable equilibrium .

Equilibrium

With a zero height of the triangle h = 0 (as it is sometimes drawn in some articles), the yoke from the triangle turns into a straight line. When turning the straight arm, the length of the shoulders changes equally, the ratio l1 / l2 does not change and the equilibrium is not established. Such a device corresponds to a state of indifferent equilibrium . When weighed on equilibrium, the position of stable equilibrium is not present and the equilibrium is determined by the indifferent position of the rocker arm with manual deflection to the left and right.

Comparator

If the pivot point is below the pivot points, then such a device works as a comparator or trigger , that is, it determines which of the two masses is greater and which is less ( quality ). Such a device corresponds to a state of unstable equilibrium .

Multiple Scales

Equilibrium conditions are completely different than equal shoulder weights.

One-heating scales with different arms, shown in the figure on the right, reduce the number of weights (weights) and the probability of losing them, that is, they have increased reliability, but have a greatly reduced range of weighed loads. The scale of scales is non-linear, compressed at the edges of the scale range and stretched in the middle part of the scale range.

Smart Scales

Smart scales - a device that can determine the number of physiological parameters of the body, transmitting data to a smartphone.

Criteria for smart scales]:

- determine not only weight, but also other body parameters (BMI, percentage of adipose, bone, muscle tissue, etc.);

- synchronized with the smartphone;

- distinguish users.

Some models of smart scales are equipped not only with sensors for the body, but also with environmental sensors, such as temperature and air quality (CO 2 content). Also, there are scales with calorie counts, inside which a nutritional guide is sewn up, for each index (food) indicated the content of proteins, fats, carbohydrates. [five]

Basic Scale Parameters

The largest weighing limit (LEL) is the upper limit of the weighing limit, which determines the largest mass measured by a single weighing.

The smallest weighing limit (LDPC) - the lower limit of the weighing limit, is determined by the minimum load, with a one-time weighing which the relative weighing error should not exceed the permissible value.

The division price d is the difference in the mass values corresponding to the two adjacent marks on the scale of the scale with an analog reading device, or the mass value corresponding to the sampling resolution of digital scales.

The price of the test division e is a conditional quantity, expressed in units of mass, used in the classification of weights and the normalization of the requirements to them.

The number of calibration marks n is the LEL / e value.

The maximum permissible measurement error is determined by the price of the calibration division e . Typically, a scale manufacturer guarantees the following relationship: d = e The lower the error, the higher the measurement accuracy.

The error of the weights in the measurement range in absolute value should not exceed the limits of permissible error given in the table according to GOST 24104-2001 (Application ceased on the territory of the Russian Federation from 01/01/2010. Now GOST R 53228-2008 is valid):

| Weighting intervals for scales of accuracy class | Limits of permissible error | |||

|---|---|---|---|---|

| special | high | average | during the initial calibration | in operation |

| Up to 50,000 e inclusive | Up to 5000 e inclusive | Up to 500 e inclusive | ± 0.5e | ± 1,0e |

| St 50,000 e to 200,000 e inclusive | St 5000 e up to 20,000 e inclusive | St. 500 e to 2000 e inclusive | ± 1,0e | ± 2.0e |

| Above 200,000 e | St 20000 e | St. 2000 e | ± 1,5e | ± 3.0e |

IP (International Protection, "Ingress") dust protection - the degrees of protection provided by enclosures (IEC 60529, DIN 40050, GOST 14254-96). Usually denoted as “IP” and two digits, the first is the degree of protection of people from access to dangerous parts of electrical equipment and the product itself from ingestion of foreign solid objects (from 0 to 6), and the second is the degree of protection from harmful effects due to water penetration (from 0 to 8). "Dust protection" have products with IP5X and higher. “Splash Protection” - products with IPX3 and higher, sealing - IPX7 and IPX8. The maximum degree of protection of electrical equipment according to GOST is IP68 (dustproof and airtight with a long stay under a layer of water 15 cm from the top point). IP69K combination (available only in DIN) - means dust-proof and waterproof when cleaned with a high-pressure jet or steam (but, generally speaking, does not guarantee tightness when in water).

Explosion protection scales Ex. To use the scales in the environment of flammable and explosive mixtures, at the enterprises of the oil refining, chemical, mining, and food industries, the weighing equipment is performed in an explosion-proof design. The presence of an Ex marking followed by numerical designation implies that there can be no spark in a scale or other equipment that is in an explosive environment that could cause an explosion or a fire of this mixture.

A tare mass sampling device is a device that allows to bring the readings of the scales to zero when the container is placed on the load receptor, with a decrease in the LEL by the tare weight.

A tare mass compensation device is a device that allows you to bring the balance to zero when the container is placed on the load receptor, without reducing the LEL .

Scale Classification

By the principle of action

According to what physical laws weighting is based on, the scales can be divided into:

- lever (based on the principle of the lever );

- spring (based on Hooke's law , for example, manual spring scales );

- strain gauge (based on the strain gauge strain conversion);

- hydrostatic (based on the action of Archimedean force , used to measure body densities );

- hydraulic [6] .

For operational purposes

According to the scope (operational purpose), according to GOST 29329-92 , the scales can be divided into the following groups:

- automobile - such scales allow to provide entrance control of incoming raw materials and control of product shipment, as well as control axial and wheel load of vehicles in accordance with legal requirements;

- luggage;

- household;

- carload ;

- trolley;

- for weighing livestock;

- for weighing milk;

- crane;

- laboratory;

- medical;

- monorail;

- palettes [7] ;

- platform;

- postage;

- commodity;

- trading;

- elevator.

- crane

By weighing accuracy

- special accuracy class (analytical - in analytical chemistry );

- high accuracy class (laboratory);

- middle class accuracy.

By way of on-site installation

- mortise;

- built-in;

- floor standing;

- desktop;

- mobile;

- suspended;

By type of balancing device

- mechanical;

- electromechanical (electronic) [8] .

By type of weighing device

- bunker;

- bucket;

- conveyor;

- hook;

- monorail;

- platform

By way of achieving equilibrium

- with automatic balancing;

- with semi-automatic balancing;

- with non-automatic balancing.

Depending on the type of reading device

- with analog reading device;

- with discrete readout device.

According to requirements

GOST R 53228-2008 [9] , which describes the general technical requirements for weights, classifies them as follows:

Accuracy class

- special;

- tall;

- average;

- usual.

Possible sources of error for mechanical scales

When working with high-precision laboratory and analytical mechanical scales, such errors are also possible:

- the error caused by balance unequalness (for equal shoulder weights);

- error caused by wear of prisms and pillows. During the life cycle of the balance, the radius of curvature of the prisms of the rocker arms increases. When the position of the rocker arm of the prism changes, it “rolls” along the pillows and the length of the shoulders changes. As a result, the division price changes and non-linearity appears when measured on an optical scale. This error is manifested in both equal-shoulder and single-shoulder scales;

- malfunction of the arresting device, pollution and gross defects (chips, chipping) of prisms and pillows lead to poor reproducibility of measurements.

Strictly speaking, it is impossible to manufacture absolutely equal-arm scales without optical readout errors, therefore, if you need particularly accurate work on such scales, you should use precise weighing methods, such as:

- weighing on one shoulder according to Mendeleev (eliminates the error of unequal arm);

- weighing at a fixed position of the rocker arm (correcting for unequalness eliminates rolling errors);

- weighing on one shoulder with a fixed position of the rocker.

Weights

(drawing from the " Bible Encyclopedia ")

Sets of weights for certain weights are called weights. Depending on the maximum and minimum weights on the scales, the weights may consist of a larger or smaller number of elements.

The modern, most common system of numerical series for weights was proposed by DI Mendeleev . It provides the minimum number of operations of imposing / lifting weights on the scales when selecting a hinge. Previously used pound weights. It included a set of weights in 1, 2, 3, 6, 12, 24 and 48 spools. In such a state of balance, not one weight was repeated, and the sum of all of them was exactly one pound. The pound was subdivided into 96 spools, and the spool into 96 shares.

Modern weights contain weights from the numerical series 1, 2 (2 weights each), 5.

Sets of weights (weights) produce different classes of accuracy. They are subject to mandatory certification and primary and periodic verification by metrological control authorities. For model and analytical weights, the material used for their manufacture is of particular importance. In order for the weights not to change their mass, it is necessary that the materials for them be:

- antimagnetic - to eliminate the influence of magnetic fields on the weighing result;

- resistant to corrosive environmental agents;

- resistant to wear during operation;

- dense in structure, in order to avoid absorption of steam, gases and moisture.

Possible sources of error for electronic scales

When using high-precision scales, such as analytical or laboratory scales, there is a probability of measurement error. The following factors can be the source of such errors:

- static buoyancy;

- using defective reference weight (used for fraud when weighing);

- dependence of indications on the position of the load on the cup (detuning of the Roberval mechanism );

- airflow, even the weakest, can affect weighing results;

- friction between moving parts of scales;

- the dust which settled on the pallet;

- scales may not be calibrated by calibration weights;

- mechanical deformation of parts due to temperature drops;

- insufficient warming up before calibration, detuning of the temperature compensation circuit;

- anomalies of the gravitational field of the Earth (the use of scales in the immediate vicinity of mountains) can affect the details of the construction of scales;

- magnetic fields from devices located close enough to the scales can affect the metal components of the scales;

- magnetic disturbances of sensors;

- the electrostatic field can affect the metallic parts of the structure;

- chemical reaction between the substance to be weighed and air (or, in the case of corrosion, by weights);

- condensation on cold objects;

- evaporation of water from warm objects;

- air convection ;

- Coriolis force from the rotation of the Earth ;

- vibrations and seismic disturbances: for example, vibrations from passing vehicles;

- scales not mounted on a horizontal level or on a soft surface (carpet or rubber covering).

See also

- Amp scales

- Trap

- Quintense Scales

- Torsion scales

Notes

- ↑ In everyday life, the concepts of weight , gravity and mass are often confused.

- ↑ 1 2 V.N. Pipunirov. The history of weights and weight industry in comparative historical lighting. M, 1955

- ↑ 1 2 3 4 - Scale History

- ↑ bezmen // Explanatory Dictionary of the Russian language : in 4 t. / Ch. ed. B. M. Volin , D. N. Ushakov (vol. 2-4); status G. O. Vinokur , B. A. Larin , S. I. Ozhegov , B. V. Tomashevsky , D. N. Ushakov ; by ed. D.N. Ushakov . - M .: State Institute "Soviet Encyclopedia" (Vol. 1): OGIZ (Vol. 1): State Publishing House of Foreign and National Dictionaries (Vol. 2-4), 1935-1940.

- ↑ Кухонные весы с подсчётом калорий: основа вашей диеты . vashtehnik.ru. Дата обращения 7 июня 2018.

- ↑ Весы (прибор) — статья из Большой советской энциклопедии .

- ↑ :Ж.р., одна буква «л» согласно «Русскому орфографическому словарю» РАН. (inaccessible link) . Дата обращения 4 июля 2012. Архивировано 4 августа 2012 года.

- ↑ Павлов, 2006 .

- ↑ ГОСТ Р 53228-2008 - скачать бесплатно . www.gosthelp.ru. Дата обращения 2 марта 2016.

Literature

- Весы // Энциклопедический словарь Брокгауза и Ефрона : в 86 т. (82 т. и 4 доп.). - SPb. , 1890-1907.

- Завельский Ф. С. Взвешивание миров, атомов и элементарных частиц. М, Атомиздат, 1970 г.

- Пипуныров В. Н. История весов и весовой промышленности в сравнительно-историческом освещении. М, 1955 г.

- Весы / Павлов С. А. // Великий князь — Восходящий узел орбиты. — М. : Большая российская энциклопедия, 2006. — С. 218—219. — ( Большая российская энциклопедия : [в 35 т.] / гл. ред. Ю. С. Осипов ; 2004—2017, т. 5). — ISBN 5-85270-334-6 .