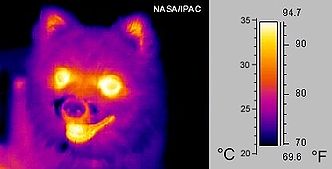

Thermal imager ( heat + lat. Vīsio “sight; vision”) - a device for observing the temperature distribution of the investigated surface. The temperature distribution is shown on the display as a color picture, where different colors correspond to different colors . The study of thermal imaging is called thermography .

Technology

All bodies whose temperature exceeds absolute zero emit electromagnetic thermal radiation in accordance with Planck's law . The spectral density of the radiation power (Planck function) has a maximum whose wavelength on the wavelength scale depends on temperature. The position of the maximum in the emission spectrum shifts with increasing temperature towards shorter wavelengths ( Wien's displacement law ). Bodies heated to the temperatures of the world around us (-50 .. + 50 degrees Celsius) have a maximum radiation in the mid- infrared range (wavelength 7..14 μm). For technical purposes, the temperature range up to hundreds of degrees, radiating in the range of 3..7 μm, is also interesting. Temperatures of about a thousand degrees and above do not require thermal imagers for observation, their thermal glow is visible to the naked eye.

Sensor

Historically, the first thermal imaging sensors for imaging were electron-vacuum . The most developed is the variety based on vidicons with a pyroelectric target. In these devices, an electron beam scanned the surface of the target. The beam current depended on the internal photoelectric effect of the target material under the influence of infrared radiation. Such devices were called pirikon or pyrovidicon [1] . There were also other types of scanning electron-vacuum tubes sensitive to the thermal spectrum of infrared radiation, for example, thermicon and filterskan. [one]

Solid state devices replaced electronic vacuum devices. The first solid-state sensors were single-element, therefore, to obtain a two-dimensional image, they were equipped with an electromechanical optical scan. Such thermal imagers are called scanning imaging cameras [1] . In them, a system of moving mirrors sequentially projects radiation from each point of the observed space onto the sensor. The sensor can be a single element, a line of sensitive elements or a small matrix. To increase sensitivity and reduce inertia, the sensors of scanning thermal imagers are cooled to cryogenic temperatures. The best cooled sensors are able to respond to single photons and have a reaction time of less than microseconds.

Modern thermal imagers, as a rule, are built on the basis of special matrix temperature sensors - bolometers . They are a matrix of miniature thin-film thermistors. The infrared radiation collected and focused on the matrix by a thermal imager lens heats the elements of the matrix in accordance with the temperature distribution of the observed object. The spatial resolution of commercially available bolometric matrices reaches 1280 * 720 pixels [2] . Commercial bolometers are usually made uncooled to reduce the price and size of equipment.

The temperature resolution of modern thermal imagers reaches hundredths of a degree Celsius.

Distinguish between observing and measuring thermal imagers. Observational thermal imagers show only the temperature gradients of the object. Measuring thermal imagers allow you to measure the temperature value of a given point of an object with an accuracy of the emissivity material of the object. Measuring thermal imagers require periodic calibration, for which they are often equipped with an integrated device for calibrating the matrix, usually in the form of a curtain, the temperature of which is accurately measured. The curtain periodically slides over the matrix, making it possible to calibrate the matrix according to the temperature of the curtain.

Optics

Since ordinary optical glass is opaque in the mid-IR range [3] , the optics of thermal imagers are made of special materials. Most often it is germanium [4] [5] [6] , but it is expensive, therefore chalcogenide glass sometimes used , zinc selenide [7] or even polyethylene . For laboratory purposes, optics can also be made from certain salts, for example sodium chloride [8] , which is also transparent in the required wavelength range.

Creation History

The first thermal imagers were created in the 30s. XX century Modern thermal imaging systems began to develop in the 60s of the XX century. The first thermal imaging sensors for imaging were electron-vacuum. The most developed pyricones ( pyrovidicons ) [1] . There were also other types of scanning electron-vacuum tubes sensitive to the thermal spectrum of infrared radiation, for example, thermicon and filterskan [1] . Then, thermal imagers appeared on solid-state sensors with optical-mechanical scanning of the field of view formed by the lens and a single-element radiation receiver. Such devices were extremely unproductive and made it possible to observe the temperature changes occurring in the object at a very low speed.

With the development of semiconductor technology and the advent of CCD photodiode cells to store the received light signal, it has become possible to create modern thermal imagers based on a CCD sensor array . This principle of imaging allowed us to create portable devices with a high speed of information processing, which allow real-time monitoring of temperature changes.

The most promising direction for the development of modern thermal imagers is the use of uncooled bolometer technology [9] , based on ultra-precise determination of changes in the resistance of thin plates under the influence of thermal radiation of the entire spectral range. This technology is actively used worldwide to create a new generation of thermal imagers that meet the highest requirements for mobility and safety of use. .

In the USSR and Russia

The first civilian thermal imagers were developed in the USSR for medical use in the Istok Scientific Production Enterprise in the 1970s. Since the late 1970s, mass production of a scanning thermal imager on a cooled solid-state sensor TV-03 began [10] . By the time of the collapse of the USSR, a wide range of civilian and industrial thermal imagers was produced [1] .

Thermal imagers for military use have been developed since the 1970s, initially in the form of aviation optical-location stations (OLS) [11] [12] . By the end of the 1980s, the first serial thermal imaging sights "Agava-2" began to be installed on tanks [13] .

The collapse of the post-Soviet industry of the 1990s and the development in the west of efficient uncooled bolometric matrices caused a significant lag in Russia in this area. Thermal imaging sensors and systems for civilian and military purposes were purchased abroad. Nevertheless, reports began to appear on overcoming technological lag and deploying the production of national sensors [14] [15] [16] .

Scope

Energy leakage control

Modern thermal imagers are widely used both in large industrial enterprises, where careful monitoring of the thermal state of objects is required, as well as in small organizations involved in troubleshooting network problems for various purposes. Thus, scanning with a thermal imager can accurately show the location of the contacts in the wiring systems.

Thermal imagers are especially widely used in construction in assessing the thermal insulation properties of structures. So, for example, using a thermal imager, you can determine the area of greatest heat loss in a house under construction and make a conclusion about the quality of building materials and heaters used.

Night Vision

Thermal imagers are used by the armed forces as night vision devices to detect heat-contrasting targets (manpower and equipment) at any time of the day, despite the usual optical masking in the visible range used by the enemy (camouflage). The thermal imager has become an important element in the sighting systems of military strike aircraft and armored vehicles. Thermal imaging sights are also used for hand small arms, although due to the high price of wide distribution they have not yet received.

Rescue Services

Thermal imagers use fire and rescue services to search for victims, identify burning areas, analyze the situation and search for escape routes.

Medicine

The development of thermal imagers for medicine was started in the USSR in the Istok Scientific Production Enterprise ( Fryazino, Moscow Region ) in 1968 . In the 1980s, methods were developed for using thermal imagers to diagnose various diseases. The TV-03 thermal imager produced in those years by the domestic industry was widely used in various medical institutions. TV-03 was the first thermal imager to be used in neurosurgery [10] . In modern medicine, a thermal imager is used to identify pathologies that are difficult to diagnose in other ways, including to detect malignant tumors.

From 2008-2009 thermal imagers also began to be actively used to isolate people infected with the influenza virus from the crowd [17] [18] .

Metallurgy and mechanical engineering

When controlling the temperature of complex processes characterized by uneven heating, unsteadiness and heterogeneity of the coefficient of thermal radiation, thermal imagers are more effective than pyrometers, since the analysis of the resulting thermogram or temperature field is carried out by a powerful human visual system.

To improve the reliability of measuring the temperature of heated metals, it is necessary to correctly select the spectral range of registration of thermal radiation [19] . The thermal radiation coefficient ε of metals heated above 400 ° C varies greatly due to the oxidation of their surface by atmospheric oxygen [20] . Therefore, to register their thermal radiation, it is necessary to choose a portion of the spectrum in which the influence of the uncertainty ε on the obtained temperature readings is minimal [19] .

In thermal imaging technology use different parts of the spectrum. When measuring low temperatures, thermal radiation is recorded in the spectral region of 8-14 μm and sometimes in the region of 3-5 μm [21] . To measure temperatures in excess of 700 ° C, high-temperature thermal imagers are used, using matrices based on Si [22] or InGaAs, which are sensitive in the near infrared region of the spectrum, where the thermal radiation coefficient of metals ε is much larger than in the region of 8-14 μm [19 ] [20] . If it is necessary to measure the true temperature, thermal imagers are used, which record thermal radiation in three parts of the spectrum.

Other Applications

- Astronomical Infrared Telescopes .

- A night driving system for easier control of the traffic situation by the driver.

- Control of electrical circuits for overheating of conductors and poor contact.

- Veterinary control.

Smartphones

In 2014, the company FLIR released a casing for Apple smartphones, in which a thermal imager is mounted [23] . In the same year, Seek Thermal released a separate thermal imaging camera for iOS and Android devices [24] . In February 2016, the first Caterpillar S60 smartphone with an integrated thermal imager developed by FLIR was announced [25] .

Images

Thermal imaging nozzle for day sights

Universal security surveillance device

Round-the-clock dual-channel thermal imaging television

Multispectral multi-purpose surveillance and target designation system

Monocular thermal imaging

24-hour thermal imaging device

See also

- Colour temperature

- Pyrometer

- Infrared radiation

- thermal radiation

- Catherine FS

Notes

- ↑ 1 2 3 4 5 6 Kriksunov L.Z., Padalko G.A. Thermal imagers: a reference book. - K., 1987.

- ↑ DARPA developing personal LWIR cameras

- ↑ Glasses absorbing the infrared part of the spectrum

- ↑ Germanium

- ↑ Germanium Windows

- ↑ Germanium Plano-Convex Lenses

- ↑ Zinc Selenide

- ↑ CRYSTALTECHNO Ltd

- ↑ Rogalski A. Infrared detectors. Singapore: Gordon and Breach Science Publishers, 2000. 681 c.

- ↑ 1 2 Devyatkov N. D. Application of electronics in medicine and biology . Electronic equipment. Ser. Microwave technology . 1993. No. 1 (455). S. 67-76.

- ↑ Su-27

- ↑ History of aviation. Hot MiG against the sky

- ↑ Thermal imagers

- ↑ Finally, Russia will have its own thermal imagers

- ↑ NGO ORION

- ↑ Tank Thermal Imagers from Schwabe

- ↑ Komsomol truth. Swine flu will not reach us through the air: a thermal imager was installed in the Nizhny Novgorod airport. . kp.ru (August 13, 2009). Date of treatment February 25, 2010. Archived February 14, 2012.

- ↑ Special Lab. Electronic flu vaccine. . operlenta.ru (January 14, 2010). Date of treatment February 25, 2010. Archived February 14, 2012.

- ↑ 1 2 3 http://www.ste.ru/siemens/pdf/rus/ardo_info.pdf (inaccessible link) Retrieved June 26, 2017.

- ↑ 1 2 Burakovsky T., Gizinsky E., Salya A. Infrared emitters: Per. from Polish - L .: Energy, 1978.

- ↑ V.V. Korotaev, G.S. and others . The basics of thermal imaging - St. Petersburg: NRU ITMO, 2012. - 122 p.

- ↑ A Unique Ultra High Resolution Thermal Imager / Mikron Infrared Inc. Thermal Imaging Division.

- ↑ FLIR One

- ↑ Seek Thermal

- ↑ Technology News - Newspaper.Ru

Literature

- Lloyd J. Thermal imaging systems. / Per. from English under the editorship of A.I. Goryacheva. - M .: Mir, 1978, p. 416.

- Kriksunov L.Z. Handbook of the basics of infrared technology, Publisher: Sovetskoe Radio, year: 1978, pages: 400.

- Gossorg J. Infrared thermography. The basics. Equipment. Application. M .: Mir, 1988.

- V.A. Drozdov, V.I. Sukharev. Thermography in construction - M .: Stroyizdat , 1987. - 237 p.

- Infrared thermography in the energy sector. T 1. Fundamentals of infrared thermography / Ed. R.K. Newport, A.I. Tajibaev, author: A.V. Afonin, R.K. Newport, V.S. Polyakov, et al. - St. Petersburg: Izd. PEIPK, 2000 .-- 240 s.

- Ogirko I. V. The rational distribution of temperature over the surface of a thermosensitive body ... p. 332 // Engineering Physics Vol. 47, No. 2 (August, 1984)