Anti- recoil devices - devices designed to mitigate shock loads on the gun carriage during recoil , converting mechanical energy into heat and serving to absorb shocks and shocks.

Content

- 1 Calculation of recoil energy

- 1.1 Calculations

- 2 History

- 3 Design description

- 3.1 Knurl

- 4 Construction Details

- 5 See also

- 6 notes

- 6.1 Sources

Calculation of recoil energy

Gases flowing from the channel of the gun’s bore act according to Newton’s III law on the barrel itself with equal and oppositely directed force. The principle of jet propulsion is implemented, which enhances the purely mechanical return on projectile departure. An accurate calculation of the total recoil energy is a complicated procedure, but in artillery science there is an empirical rule that 3% of the muzzle energy of a projectile goes into mechanical energy of recoil. For example, for a 122 mm A-19 gun, the total mechanical recoil energy is 0.03 × 8 MJ = 240 kJ . This corresponds to the potential energy of a cargo weighing 1 ton , raised 24 m above ground level, taken as the zero point of reference energy. Under normal conditions, this would be enough to crush or break the guns into pieces. However, the recoil devices of this gun (it is not equipped with a muzzle brake) successfully extinguish this recoil energy and use it to bring the recoil part of the gun to its original position before the next shot.

The full distribution of energy during the shot varies depending on the type of weapon, propellant charge and projectile, but in general the picture looks something like this:

- 20-40% goes into the kinetic energy of the projectile

- 15-25% is spent on heating the projectile and the barrel by mutual friction

- 5% goes to the mechanical energy of the recoil of the gun

- other (sometimes up to 60%) - dissipation into the atmosphere

Calculations

Let's consider two states of the system - at the moment “0” of the complete combustion of the propellant charge, but when the projectile is still stationary and at the moment “1” of the projectile’s departure from the gun. We introduce two assumptions. The first will be the complete combustion of the propellant charge before the projectile begins to move. In fact, combustion still occurs when the shell has already begun to move. However, the exact calculation in this case is very difficult, since it is a self-consistent task. To solve practical problems, the assumption described above is considered quite suitable. The second assumption is the absence of heat loss, which violates the purely mechanical laws of conservation of energy and momentum. As applied to practice, this means that a top-down evaluation of the recoil energy and efficiency of the gun is made.

At the moment “0”, a shell of mass m sn , recoiling parts of a gun of mass M and powder gases of mass m pg do not have mechanical velocities in the inertial reference frame associated with the Earth. So all impulses are equal to zero.

At the moment “1” the projectile gained speed v , the recoiling parts (in the absence of recoil devices) received speed V. Accordingly, the projection of the projectile momentum p sn on the axis directed along the channel of the gun’s barrel is m sn v , and the projection of the momentum of the recoil parts P = - MV . According to the artillery model of the distribution of the velocity of the ordered movement of powder gases along the channel of the gun’s barrel, this velocity is zero at the bolt and linearly increases to v at the muzzle. The calculation of the total momentum of the powder gases by integration along the barrel of the gun gives the value p pg = 0.5m pg v . Applying the law of conservation of momentum, we obtain

m cn v + 0.5m pg v = MV

From this equation it is possible to calculate the speed of the retractable parts and the value of the kinetic energy of recoil E = 0.5MV² from the projectile departure, which is needed during the design of the recoil device of the gun and for the possible equipping of the barrel with a muzzle brake . These devices are needed to mitigate the shock loads on the carriage during recoil. Similarly, by calculating the useful kinetic energy of the projectile e = 0.5m cn v² , it is possible to obtain the efficiency of the gun by dividing e by m pg Q (since the mass of powder gases is equal to the mass of the propellant charge).

History

- ROLLING OF A CARRIAGE, moving it back during a shot due to the pressure of gunpowder. gases to the bottom of the channel.

- If the CARRIAGE OF THE CARRIAGE meets resistance only in the friction of the carriage on the ground, then its length is very significant (several compression ).

- In order to avoid the expense of a lot of work and time for rolling, in order to eliminate the knocking down of the pickup with each shot,

- as well as economical. considerations at the carriages of the fortress and the shore. art ries (for large O., casemates must be made longer,

- and the Walgangs are wider) and finally

- for the sake of better shelter, the installations behind the parapet have always sought to reduce the length of the O. with the help of specials. means

- like, for example, trousers [Comm. 1] , wheeled. brakes, sliding wedges [Comm. 2] , the front tilt is swivel. frames (see Swivel frame [Comm. 3] ),

- compressors and, finally, hydraulic, buffer , spring and pneumatic brakes.

- In modern times, a quick-fire. the carriages Kickback of the entire carriage when fired completely destroyed,

- and to weaken the excessively high stresses arising in the carriage, the gun itself rolls along the cradle along its axis,

- transferring the work of recoil to the brake, and then automatically quickly returns to its original position by the knobs.

- If the CARRIAGE OF THE CARRIAGE meets resistance only in the friction of the carriage on the ground, then its length is very significant (several compression ).

(the first serial gun of the modern type was the rapid-firing gun of Baranovsky arr. 1877).

Retractable wedges.

Retractable wedges.

Swivel frame . The 1840 Columbiad , designed by George Bomford.

Fortress carriage for a 6-inch cannon on a turntable.

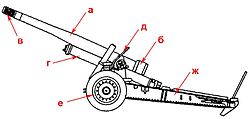

Design Description

| When rolling back. The barrel under the action of powder gases rolls back when fired together with the recoil brake cylinder fixed in the holder of the breech ring with a spindle and a cylinder of the recuperator. The recoil brake rod and the knurled rod fixed in the cradle cover remain stationary. The fluid located in the brake cylinder between the piston and the oil seal passes through six inclined holes in the rod head. Having passed these openings, most of the fluid will pass through the annular gap between the control ring and the spindle into the rear of the recoil brake cylinder, where a rarefied space forms. A smaller part of the liquid will pass between the spindle and the inner surface of the stem through eight inclined holes, then it will enter the moderator cavity, depress the valve and fill the moderator stem cavity. The energy of movement of the rolling parts is absorbed due to the hydraulic resistance of the liquid sprayed through the changing gap between the control ring and the spindle of the recoil brake. As the length of the rollback increases, the annular gap between the spindle and the control ring decreases, disappearing towards the end of the rollback. As a result, there is a smooth braking of the rollback. Simultaneously with the action of the recoil brake, the action of the knurl occurs, which consists in the following: the fluid located in the knurl working cylinder between the packing cone and the piston is forced out through the holder hole into the middle cylinder, and from the middle cylinder through the hole with the nozzle, into the outer cylinder and even more compresses the air inside it under pressure, thereby accumulating the necessary energy for rolling the rolling parts of the gun. |

| When rolling. Compressed air in the outer cylinder of the recumbent, trying to expand, presses on the fluid, which transfers pressure to the piston rod and the sealing device in the stuffing box. But since the piston with the rod is stationary, then under the pressure of the fluid on the sealing device, the recycle cylinders together with the barrel and the recoil brake cylinder will return to their original position. The fluid located in the cylinder of the recoil brake behind the piston will go to the front of the cylinder through the existing annular gap between the spindle and the control ring. The moderator valve, under the action of the valve spring, closes the cavity of the moderator, and the part of the liquid that has got into the moderator space is sprayed only through the gaps formed grooves of variable depth between the inner surface of the stem and the outer surface of the shirt moderator. The resistance of the liquid to spraying through the changing gaps between the stem and the moderator’s jacket provides braking. The smoothness of the run is achieved by the fact that at the end of the run grooves of variable depth converge to nothing. With intense shooting, the fluid in the pullback brake warms up and its volume increases, which can cause a shortage of the barrel. To avoid this, there is a compensator in the recoil brake, into which excess fluid from the moderator space leaves through an open hole in the valve body and connecting tubes, squeezing the piston of the compensator, which is under pressure from the springs. If the rate of fire decreases and the fluid cools in the recoil brake cylinder, the volume of the brake cylinder will be replenished with fluid from the compensator. The compensator piston, under constant pressure of the compressed springs, will displace the excess fluid back into the moderator space, and from there into the recoil brake cylinder. |

[one]

Knurl

Spring-loaded knurls were often used on guns from the First World War, but they turned out to be unreliable and eventually were replaced by pneumatic knurls.

For example, the Mark 12 5 "/ 38 gun (an American 127-mm naval gun of the Second World War period) is equipped with a hydraulic recoil brake . It consists of two pistons in the hydraulic cylinder that absorb the main energy of the recoil. They also dampen the impact of the pneumatic recuperator mechanisms when returning the barrel to the starting position.

Pneumatic knurling is a chamber filled with high pressure air. In its rear part is a piston. During the rollback, the piston compresses the air in the recuperator, and then returns the barrel to its original position. In the initial position, the pressure in the roll chamber is 10 MPa. During the rollback, the pressure in the knurl increases to 15 MPa.

Construction Details

- The recoil devices of the 76-mm regimental gun of the 1927 model included a hydraulic recoil brake and a pneumatic knurling . 1.3 liters of fluid in the recoil brake, 3.6 liters in the recuperator. The barrel and recoil devices are mounted on a slide that moves when rolling back in the cradle . The weight of the rolling parts (with the barrel ) is 275 kg. The maximum rollback length is 1030 mm, normal - from 930 to 1000 mm.

- Anti-recoil devices 122 mm guns arr. 1931 consisted of the following mechanisms:

- spindle-type hydraulic recoil brake , filled with spindle oil in an amount of 22 l;

- hydropneumatic recuperator , filled with glycerin liquid Steol (22 l) and air under a pressure of 45 atm.

- Anti-recoil devices are mounted in a trough cradle under the barrel . The cradle with trunnions with roller bearings lies in the trunnion sockets of the upper machine and engages in a sector with the shaft of the lifting mechanism. During the rollback, recoil devices remained motionless.

- Anti-recoil devices 280 mm mortars of the 1939 model (Br-5) are air-hydraulic. The brake and recoil brake cylinders are installed in couplings secured by gujouns to the cradle . The cradle with trunnions lies in the trunnion sockets of the upper machine and its sector is connected movably with the gear of the main shaft . The hydraulic kickback brake contains 41 liters of spindle oil . Hydropneumatic paddle, contains 63 l of spindle oil, air pressure - 40 atm. Rollback at elevation angles from 0 to 30 ° is long (1300-1410 mm), at elevation angles from 30 ° to 42 ° variable (850-1410 mm), at elevation angles from 42 ° to 60 ° short (850-880 mm) . Anti-recoil devices during rollback are motionless. Unlike the B-4 howitzer gun carriage and the Br-2 gun, the recoil brake of the Br-5 howitzer carriage has keys of variable cross-section, which makes it possible to rearrange the barrels of different guns to the same gun carriage only in the factory (replacement of the recoil brake is necessary) .

See also

- A recoilless gun is a gun that does not have a recoil when firing. This effect is achieved due to the removal of part of the powder gases through a special nozzle in the breech of the barrel, as a result of which a reactive force is created that balances the recoil force.

- Damper

Notes

- ↑ BRYUK (English Broock), thick hemp. kanat, primѣnyavshіsya b marine. and krѣp. art for limited rollback smoothly. gun on frame. With the introduction of all kinds of brakes, dying to roll back, B. there was still some time to protect. remedy in case of failure of the brake. We’ll lie. design B. is absent.

- ↑ ROLLING WEDGES, used in siege, crepe. and shore. art ries for self-rolling tools and partly to reduce recoil. Introduced in 1876 with the adoption of the siege. and crepe. Art-ries of platforms new facilitated. type instead of the old long, located obliquely to the horizon. The first rollback. K. were made of iron or wood, dl. up to 10 ft., high 2½ ft. That means. K.'s weight (couple approx. 20 pd), inconvenience of transportation and difficulty of the rules. installing them behind the wheels of the carriages (there were cases of jumping off and overturning the carriages) were forced in the 80s. XIX century abandon K. and take hydraulic. brakes, which reduced the length of the rollback to 4 ft., and for self-rolling carriage introduced b. short K. (length 4 ft., height 1 ft.), significantly less. weight.

- ↑ TURNING FRAME, lower part of the gun carriage for large guns. calibers; lightens the sides. (horizon.) aiming the gun and rolling the gun carriage after firing, for which it is placed on the rollers and tilted in front.

Sources

- ↑ Ivanov V. A., Gorovoi Yu. B. Arrangement and operation of artillery weapons of the Russian Army: Textbook . - Tambov: Publishing House of TSTU, 2005. - 260 p. Archived January 18, 2012 on the Wayback Machine