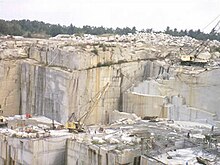

Career (from fr. Carrière ), option: open pit - a set of mine workings formed by mining in an open way ; opencast mining enterprise [1] .

A coal mine is called a coal mine [1] .

As a mine is allocated a mine field , so a career is allocated a mining allotment . The principle of open-cast mining is that the more powerful layers of empty rocks covering the minerals located on top are divided into horizontal layers within the mining allotment - ledges , which are pulled out sequentially in the direction from top to bottom, ahead of the lower layers by the upper ones. The height of the ledge depends on the strength of the rocks and the equipment used and ranges from several meters to several tens of meters [2] .

History

Open pit mining is known from the Paleolithic era. The first big careers appeared in connection with the construction sites in ancient Egypt of the pyramids. Later, in the ancient world, marble was mined on a large scale in quarries. Expanding the scope of the open-pit mining method with the help of quarries held up to the beginning. XX century, in the absence of highly productive machines for removing and moving large volumes of overburden. At the end of the 20th century, 95% of building rocks, more than 70% of ores, 90% of brown and 20% of coal were mined in quarries [3] .

The main explosives used in quarrying in the Soviet Union were ammonal and ammonites in the 1920s, dynamons in the 1930s, hydroxyquiquites and ammonites during the Great Patriotic War , and igdanite from 1956 to 1960 [ 4] .

Career Elements

Elements of the quarry ( English open-pit elements , German Tagebauelemente ) - spatial components of the quarry, which exhaustively characterize its geometry. The main elements (Fig. [5] ):

- working (1) and non-working (2) side of the quarry;

- sole or bottom (3);

- upper and lower contours (4) quarry;

- ledges (5.6);

- sites (7.8), [5]

Quarry Bottom

The bottom of the quarry is the platform of the lower ledge of the quarry (also called the sole of the quarry). Under the conditions of development of steep and inclined mineral bodies, the minimum dimensions of the open pit bottom are determined taking into account the conditions of safe removal and load of rocks from the last ledge: not less than 20 m in width, not less than 50-100 m in length .

Under conditions of the development of morphologically complex deposits of significant extension, the bottom of the quarry may have a stepped form.

Career Depth

The depth of the pit is the vertical distance between the level of the earth's surface and the bottom of the pit or the distance from the upper contour of the pit to the bottom. Distinguish between design, final and ultimate pit depth .

The deepest quarries in the world reach a depth of almost 1 km. The deepest quarry is Bingham Canyon ( Utah , USA), the Chukikamata quarry (Chile) has a depth of more than 850 m. [6]

Pit Margin

The open pit boundary contour is the open pit contour for the period of its repayment, that is, termination of work on the extraction of minerals and stripping .

Technology and career management

The quarry is a system of ledges (usually upper — pedigree or overburden, lower — mining), which are constantly moving, providing excavation of the rock mass in the contours of the quarry field.

The movement of rock mass is carried out by various modes of transport. Transport connections in the quarry are provided by constant or sliding exits, and with the surface - by trenches. During operation, the working ledges are moved, resulting in increased space. During overburden operations, overburden is moved to dumps, which are sometimes placed in a worked out space. With a pit depth of up to 100 m with strong containing rocks at a cost of 1 m³ overburden up to 25-30% is occupied by drilling and blasting operations , 12-16% - excavation , 35-40% - transport and 10-15% - the construction of the quarry itself. With increasing depth of the quarry, part of the cost of transport increases to 60-70%.

For drilling blast holes in a quarry, small, medium (DM 45, SBU-100, ROC L8) or large class drilling rigs weighing up to 130 tons (type SBSh-250 or Pit Viper) are used. As explosives, granular ammonium nitrate granulites, grammonites (a mixture of nitrate with TNT) and water-filled explosives (in flooded wells) are used. The main mining and loading equipment for coal and ore mining is electric excavators with a cable drive and a bucket with a capacity of 15-30 m³ with a boom length of up to 26 m. At the same time, hydraulic straight mechanical shovels with buckets with a capacity of 10-38 m³ are very common. Used single bucket loaders with buckets with a capacity of 4-20 m³. In stripping operations, more and more powerful shovels and draglines are introduced (for example, overburden shovels weighing 12 thousand tons with a bucket with a capacity of 135 m³ are used with a drive power of 22 thousand kW and a dragline weighing 12 thousand kW and a dragline weighing 12 thousand tons with a bucket with a capacity of 168 m³ with a boom length of 92 m).

Stream technology at the quarry is achieved by the use of rotary excavators (with a rotor diameter of 22 m and buckets with a capacity of 6.6 m³ the daily output of the machine is up to 240 thousand m³). On quarries of medium and low power, compact rotary excavators with reduced operating parameters show high efficiency.

In quarries with strong rocks, the largest volume of traffic is carried out by heavy dump trucks. Mining dump trucks with a carrying capacity of 100-155 tons are a common means of transport. Thanks to their maneuverability and power, they are able to overcome steep slopes. 200-300-ton dump trucks are also in operation. To transport the rock mass from the quarry, railway traction units with a coupling mass of 360 tons, dumpcars with a lifting capacity of up to 180 tons are used. Self-propelled mining crushers are used on caterpillar, wheeled and walking-rail with a weight of up to 600 tons and a capacity of 5 thousand tons per year. The use of crushing aggregates in the quarries allows you to move to a wider use of conveyor systems.

Career Area

The working area of the quarry is the area in which overburden and mining operations are carried out. It is characterized by a combination of overburden and mining ledges that are simultaneously in operation. The position of the working area is determined by the elevations of the working ledges and the length of their front of work. The working area is a moving and time-varying surface, within which work is carried out on the preparation and excavation of the rock mass. It can cover one, two or all sides of the quarry. During the construction of a quarry, the working area, as a rule, includes only overburden ledges, and by the end of the mining and capital works - and mining. The number of overburden, mining and mining-preparatory faces in the working area cannot be set arbitrarily, since the implementation of plans for certain types of work depends on this. In the working area of the quarry, each excavator in the process of work occupies a certain horizontal area, which is characterized by the width of the working platform and the length of the excavator block.

When developing horizontal and flat deposits of small and medium power, the altitude of the working area of the quarry remains unchanged. During the development of inclined and steep deposits, as well as powerful isometric deposits, the working area gradually decreases along with an increase in the depth of the quarry.

Career advancement

Moving the front of work in a quarry is one of the indicators of the intensity of field development. The advancement of the front of work in a quarry is characterized by speed, that is, the distance of movement of the front of mining operations, expressed in meters per unit time (for the most part - per year). The speed depends on the scale of work, the type and design of the loading and transport equipment that is used, the method of moving the front of the mining operations and the height of the benches that are being worked out. There are fan, equilateral and mixed advancement of the front of work in a career.

Fan movement - moving the front of mining during the development of a quarry field (part of it) of a rounded shape, which is characterized by a higher speed of moving front sections separated from the turning point (moving the front in the plan of “fan”, “along the fan”).

Equivalent front movement - moving the front of mining parallel to one of the axes of the quarry field from one of its borders to another or from an intermediate position to the contours.

Mixed front movement - a combination of different schemes for moving the front of mining operations, for example, equilateral and fan.

Career Deformation Depth

The depth of deformation development in the quarry is the horizontal distance from the initial position of the upper edge of the slope (upper edge of the quarry contour) to the last crack, which is visually traced in the direction opposite to the direction of movement of the displaced masses of the slope .

See also

- Coal mine

- Quarry Kennecott Bingham Canyon Mine

- Repnyanskoye career management

Notes

- ↑ 1 2 Quarry // Great Soviet Encyclopedia : [in 30 vol.] / Ch. ed. A.M. Prokhorov . - 3rd ed. - M .: Soviet Encyclopedia, 1969-1978.

- ↑ Technology of mining in quarries (opencast mines) (Inaccessible link) . Date of treatment June 30, 2017. Archived June 27, 2017.

- ↑ Quarry. Mining Encyclopedia

- ↑ Rosentreter B.A. , Fedorov A.S. Institute of the History of Natural Science and Technology (USSR Academy of Sciences). Mining and metallurgy engineering (Russian) . - Publishing House "Science", 1968. - S. 166. - 404 p. - (Essays on the development of technology in the USSR).

- ↑ 1 2 uk: Image: Elem.JPG

- ↑ The worlds deepest, biggest and deadliest open pit mines

Literature

- Melnikov N.V. Handbook of an engineer and technician for open cast mining, 4th ed. - M. , 1961.

- Rzhevsky V.V. Technology, mechanization and automation of open pit mining processes. - M. , 1966.

- Rzhevsky V.V. Technology and complex mechanization of open cast mining. - M. , 1968.

- Kuleshov N.A., Anistratov Yu. I. Technology of open cast mining. - M. , 1968.