A fuel assembly (FA) is a machine-building product containing fissile materials and designed to produce thermal energy in a nuclear reactor through a controlled nuclear reaction .

Usually it is a tetrahedral ( PWR ) or six-sided ( VVER ) fuel rod bundle 2.5-3.5 m long (which approximately corresponds to the height of the core) and a diameter of 30-40 cm, made of stainless steel or zirconium alloy (to reduce neutron absorption )

Fuel elements are assembled in fuel assemblies to simplify the accounting and movement of nuclear fuel in the reactor. One fuel assembly usually contains 18 ( RBMK ), 90-313 ( WWER ) fuel rods, and 163–1693 fuel assemblies are usually placed in the reactor core.

Content

- 1 World suppliers of fuel assemblies [1] [2]

- 2 Russian fuel assemblies

- 2.1 fuel assemblies of VVER-440 reactors

- 2.2 fuel assemblies of VVER-1000 reactors

- 2.2.1 TVSA

- 2.2.2 TVSA-ALPHA

- 2.2.3 TVSA-T

- 2.2.4 TVSA-U

- 2.2.5 TVSA-PLUS

- 2.2.6 RK-3

- 2.2.7 HTS

- 2.2.8 TVS-2

- 2.2.9 TVS-2M

- 2.3 fuel assemblies of PWR reactors

- 2.3.1 TVS-square

- 2.4 fuel assemblies of RBMK reactors

- 3 fuel assemblies of other countries

- 3.1 TVS-W

- 4 notes

- 5 Links

World suppliers of fuel assemblies [1] [2]

- Areva ( France ) - 31% of the world market [3]

- Toshiba ( Japan ) - in addition to its own facilities, the current owner of Westinghouse

- Westinghouse Electric Company ( USA ) - together with Toshiba 26% of the global market

- TVEL ( Russia ) - 17% of the world market, almost 100% of the fuel supply market for nuclear power plants with VVER reactors , 100% - for nuclear power plants with RBMK reactors , as well as some other types of reactors [4] .

- Japan Nuclear Fuel Limited (Japan) - 17% of the global market

- Mitsubishi Heavy Industries (Japan)

- Hitachi (Japan)

- Nuclear Fuel Industries (Japan)

- General Electric (USA)

- Babcock and Wilcox (USA)

- Cameco ( Canada )

- CNNC ( China )

- Siemens ( Germany )

- British Nuclear Fuels ( UK )

- FCN ( Romania )

- ENUSA ( Spain )

- Korea Nuclear Fuel ( South Korea ) - Korean monopolist

- Nuclear Fuel Complex ( India ) - Indian monopolist

- BelgoNucléaire ( Belgium ) - production of MOX fuel [5]

- Duke Cogema Stone & Webster (USA) - MOX fuel production [6]

- Thorium Power Inc (USA) - production of promising thorium fuel

Russian fuel assemblies

VVER-440 fuel assemblies

A VVER-440 fuel assembly consists of a bunch of fuel rods, a head, a shank and a cover. The fuel rods in the bundle are located on a triangular lattice and are interconnected by "honeycomb" type spacing grids fixed to the central pipe and a lower support grid fixed to the shank. The head and shank of the fuel assembly are rigidly connected over a hexagonal surface to the cover, which is the supporting structural element. The bundle consists of 126 fuel elements.

VVER-1000 fuel assemblies

The VVER-1000 fuel assembly is an active design of 312 fuel rods (there is an option with 313 fuel rods) mounted in a frame of 18 guide channels, several (up to 15) spacers and one lower grating. The fuel elements of VVER-1000 fuel assemblies can contain up to 27 fuel rods (fuel elements with uniformly integrated gadolinium oxide [7] , used as a burnable absorber, in fuel from enriched uranium dioxide). The TVSA and its variants described above do not relate to the VVER-440 reactor installation, but also to the VVER-1000. Only RK-2 and RK-3 - working cassettes of the second and third generations, respectively, belong to VVER-440.

The end parts of the fuel assemblies serve to fix the cartridge in the mounting sockets of the core. The upper end part (head) provides interaction with the reactor internals and the fuel assemblies are pressed up from the ascent, as well as a detachable connection to the fuel assembly frame. The lower end part (shank) provides the specified location of the cartridge in the active zone, as well as the organization of the coolant duct.

The main structural features of the domestic design of fuel assemblies are associated, first of all, with the shape of its cross section. Unlike world analogues based on a rectangular shape, VVER-1000 fuel assemblies have a hexagonal (hexagonal) section. All things being equal, the hexagonal shape of the fuel assembly provides a higher uniformity of the fuel element field and guarantees the safety of the fuel assembly during transport and technological operations during its manufacture and during operation at nuclear power plants.

TVSA

An alternative design fuel assembly with a rigid skeleton formed by six angles and spacer grids. The main emphasis was placed on increasing the burnup depth, increasing operational reliability and enhancing the flexural rigidity of fuel assemblies. The completed modernization of the assemblies made it possible to extend their service life to 4-5 years, and also provided the opportunity to work in maneuverable mode (daily change in the power of the power unit ).

Development of the OKBM named after I. I. Afrikantov .

TVSA-ALPHA

The evolutionary development of the basic design of TVSA. TVSA-ALFA is equipped with eight spacer grids of increased height with optimized cell geometry, fuel rods with a cladding of smaller thickness and tablets without a hole.

TVSA-T

TVSA with up to eight spacing grids. Modification of TVSA for deliveries to Temelin NPP (Czech Republic) to replace fuel for the American company Westinghouse.

TVSA-U

TVSA with an extended active part.

TVSA-PLUS

The developed design of TVSA designed for operation in the 18-month fuel cycle when operating at a capacity of 104% of the nominal.

RK-3

Third generation uncased fuel assembly. The technical design of the cartridge is based on the operating experience of the complex of second generation cartridges and the technical solutions embodied in the WWER-1000 cartridges (TVSA and TVS-2)

UTVS

Unlike the standard VVER-1000 fuel assemblies, the UTVS frame is made of zirconium, and not stainless steel. In UTVS, gadolinium oxide is used as a burnable absorber, evenly distributed over the volume of fuel pellets of several tegs (fuel elements with gadolinium). UTVS is a collapsible fuel assembly, that is, if a leaking fuel element is detected, the cartridge can be repaired by replacing a damaged fuel element with a sealed one.

UTVS was developed at OKB Gidropress jointly with TVEL OJSC.

TVS-2

A fuel assembly with a rigid frame formed by welding of twelve spacing grids to the guide channels. It is an evolutionary development of the designs of the previous case-free fuel assemblies (TVS-M, UTVS), compared with which no new elements have been added to it. All new qualities are obtained through the use of solutions that have proven themselves in operation and improve the design of individual constituent elements.

Development of OKB Gidropress ( Podolsk , Moscow Region). TVS-2 has been in operation since 2003 at the Balakovo NPP. In 2007, all units of the Balakovo NPP were transferred to TVS-2. In 2007, power unit No. 1 of the Volgodonsk NPP was transferred to this type.

TVS-2M

Modification of the fuel assembly-2, in the fuel assembly-2M the end parts are shortened and, accordingly, the fuel column of the core is elongated, down by about 100 mm and up by about 50 mm, and the 13th grating at the bottom is introduced, which fixes the beam in the zone of hydrodynamic instability. In addition, spacer grids are optimized to reduce hydrodynamic drag. The purpose of the TVS-2M is an 18-month fuel cycle. In operation since 2006 (power unit No. 1 of the Balakovo NPP). The units operating on TVS-2 are transferred to work with TVS-2M: power units No. 1-4 of the Balakovo NPP, power unit No. 1 of the Rostov (Volgodonsk) NPP. Power unit No. 2 of the Rostov NPP was commissioned with a core completely composed of TVS-2M. TVS-2M is a prototype for TVS NPP-2006.

PWR fuel assemblies

TVS-square

TVS-Kvadrat is a project of TVEL OJSC for the creation of fuel for nuclear reactors of western design. The TVS-Kvadrat design for PWR reactors uses uranium dioxide fuel enriched in U-235 to 5% with the addition of gadolinium.

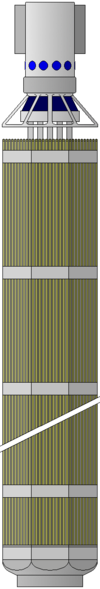

RBMK fuel assemblies

Each assembly includes 18 rod fuel rods . The fuel cladding is filled with uranium dioxide tablets.

1 - distance fittings;

2 - the shell of the fuel rod ;

3 - tablets of uranium dioxide .

TVS from other countries

TVS-W

TVS-W is a generic name for VVER fuel assemblies manufactured by Westinghouse, which were occasionally delivered to Finland's Loviisa NPPs (with VVER-440 ), Temelin NPPs ( Czech Republic ) and the South Ukrainian NPP (both with VVER-1000 ). In all cases, the fuel assemblies had a different design.

After big problems with the reliability of operation at the Temelin NPP (failure-shortfall of 51 “control rods” from 61 to the bottom end in 2007 at the Temelin NPP due to bending of the guide channels in the fuel assembly-W), the fuel was unloaded ahead of schedule and by the operating organization Temelin NPP held a tender, according to which since 2010 TVS-W have been replaced by TVSA. Among the main shortcomings, experts note the insufficient rigidity of the fuel assembly-W.

In 2008, the operating organization of Ukrainian NPPs NNEGC Energoatom signed a contract for delivery in 2011–2015. at least 630 TVS-W2 for at least 3 power units with VVER-1000 . Currently, 42 assemblies are undergoing trial operation at the South Ukrainian NPP.

Notes

- ↑ Nuclear fuel processing & services . World Nuclear Association . Date of treatment November 1, 2010. Archived on February 8, 2012.

- ↑ Westinghouse World View (inaccessible link) . Westinghouse Electric Company (April 2005). Date of treatment October 18, 2010. Archived February 8, 2012.

- ↑ LE BUSINESS GROUP AMONT (French) . Areva . Date of treatment November 1, 2010. Archived on February 8, 2012.

- ↑ Metrological support of the TVEL Fuel Company . TVEL (May 2010). Date of treatment November 1, 2010. Archived on February 8, 2012.

- ↑ Welcome . BelgoNucléaire . Date of treatment November 1, 2010. Archived on February 8, 2012.

- ↑ Use of Mixed Oxide Fuel in Power Reactors . Nuclear Regulatory Commission . Date of treatment November 1, 2010. Archived on February 8, 2012.

- ↑ VVER active zones for nuclear power plants / Shmelev V.D., Dragunov Yu.G., Denisov V.P., Vasilchenko I.N .. - Moscow: Akademkniga Research and Development Center, 2004. - P. 106. - 220 p. .